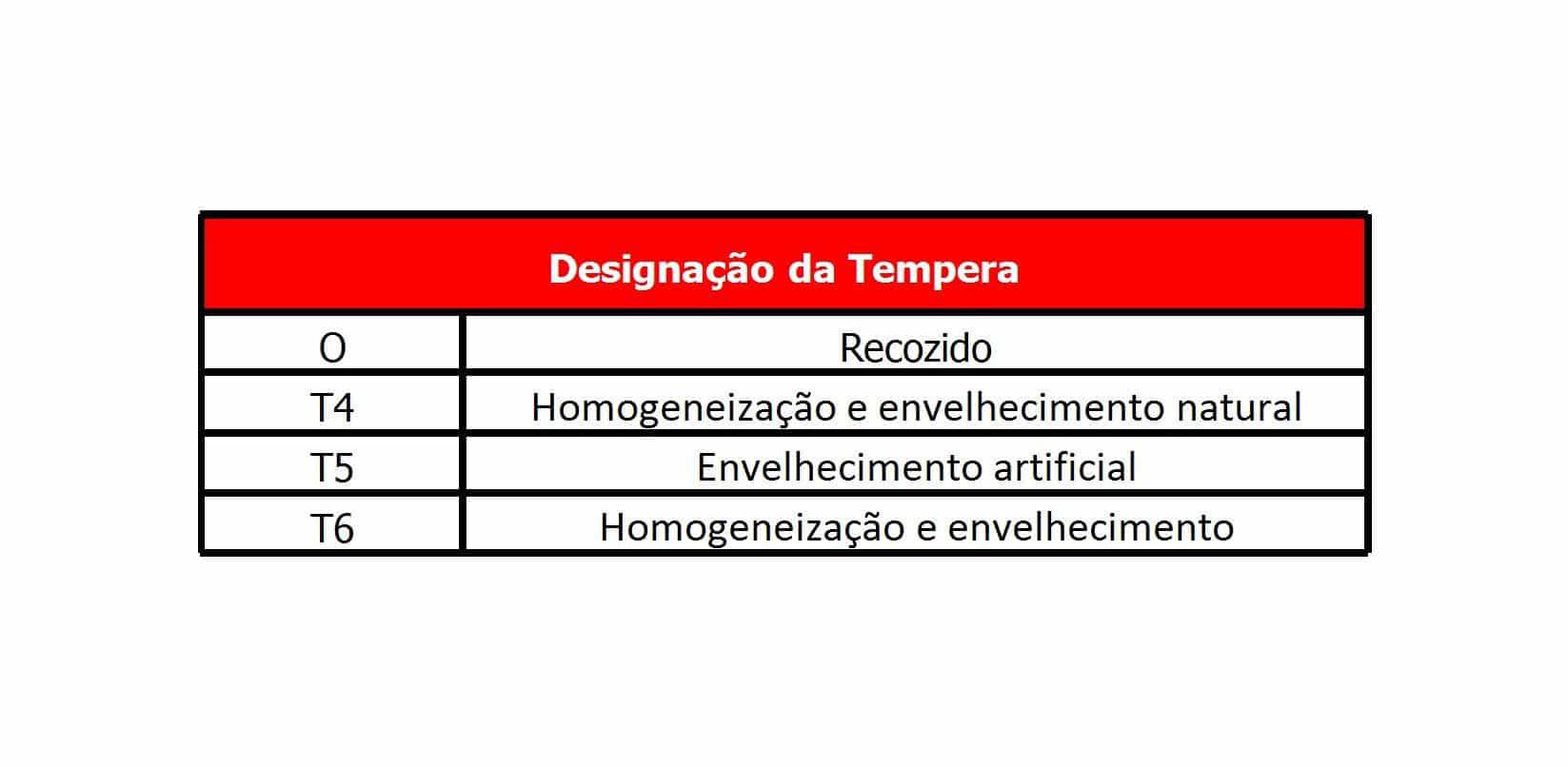

The extrusion process involves the purchase of aluminium-based raw material in the form of a billet which, after extrusion, originates the aluminum profiles. Several alloys and different heat treatments can be used, depending on the mechanical characteristics desired.

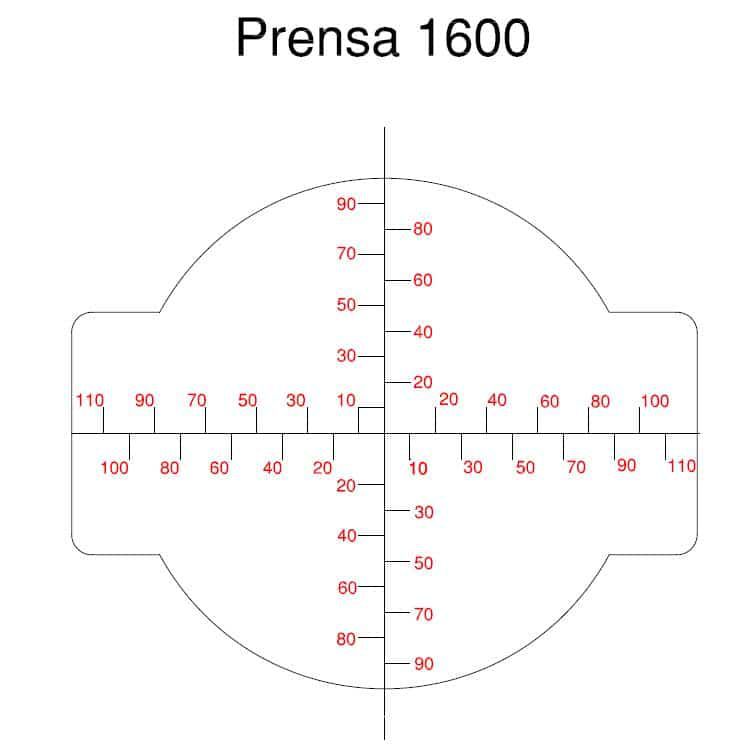

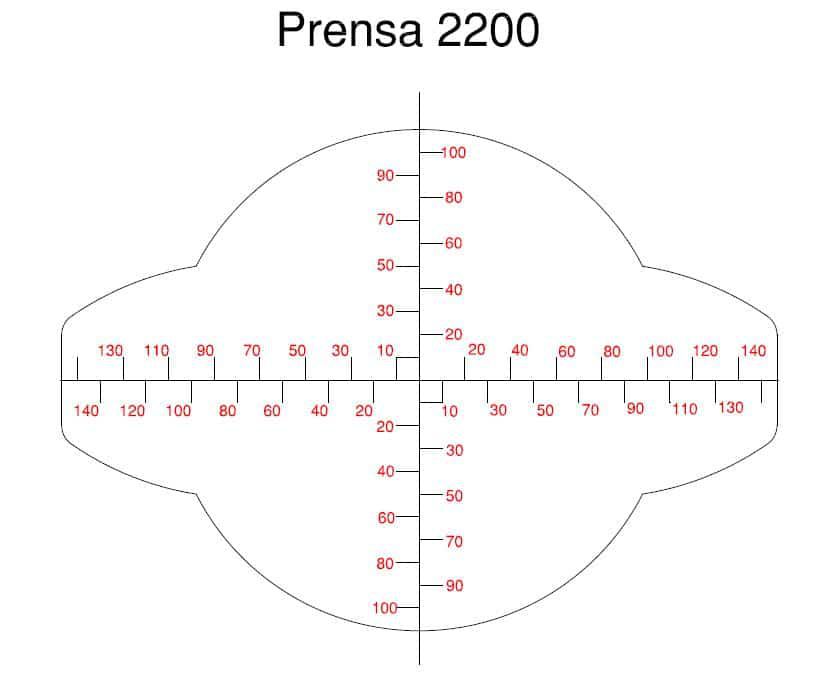

In this procedure, the aluminum billets are inserted into a specific oven for them, which feeds the press, giving rise to the desired shape of the profile, using a die. The profile leaves the discharge table continuously, where it is stretched and subsequently cut to standard measure or to the one requested by the customer.

Then the profiles are then placed in containers, to be subjected to hardening in an oven that gives them the desired mechanical characteristics.

TAFE treats its designs with profound respect and commits to deliver, within the agreed deadlines, its profiles in strict compliance with yours specifications.

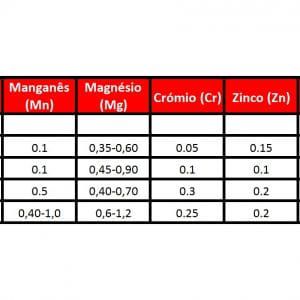

Tafe manages to extrude profiles in the 6XXX series alloy, the main elements of which are silicon (Si) and magnesium (Mg), making the profiles more suitable for heat treatment (thermal rupture) and in this way more versatile in the final applications. The alloys produced by us are:

The alloys produced by us are:

* EN-AW 6060 (Al MgSi0, 5) DIN 3.3206: Versatile alloy and used in moderated mechanical properties applications. Used in construction and industry profiles.

* EN-AW 6063 (Al Mg0, 7Si) DIN 3.2315: Very similar to Alloy 6060, presented with superior mechanical properties used in diversified applications in the automotive industry and in the industry in general.

* EN-AW 6082 (Al Si1MgMn) DIN 3.2315: By adding manganese to its chemical composition, it becomes the alloy with higher mechanical properties of this series. It is used in structural applications in the construction, transport industry and general

industry, as in machined parts for the automobile industry.

* EN-AW 6005 (Al MgSi0, 7) DIN 3.3210: Medium resistance alloy and used in applications where structures can be subjected to impacts or overloading.

Our Presses